Education Discount on Enterprise Licenses of BIN95’s Automation Training Course Software Series

A jaw-dropping offer for ‘Tech College Instructors’, and ‘Company Training and Development Managers.’ Purchase ‘The Maintenance Technician Training Software Bundle’ today to avail of the discount. No hidden terms and conditions or extra charges.

50% Discount Expires Dec 2022

They are currently offering industrial automated control systems curriculum/courseware unlimited students Site and Enterprise Licenses. Until the end of the year, the Maintenance Technician Training Software Bundle is offered at a flat 50% off the perpetual Enterprise Licenses.

LAS VEGAS (BIN95) JUNE 09, 2023

Bin95 has now emerged as a reliable educational licensing company that is currently offering 100+ training products in popular fields like mechanical, maintenance, engineering, automation, and many more. They are currently offering industrial automated control systems curriculum/courseware unlimited students Site and Enterprise Licenses. Until the end of the year, the Maintenance Technician Training Software Bundle is offered at a flat 50% off the perpetual Enterprise Licenses. Obtaining an Enterprise License will allow a school or company to incorporate a stellar curriculum of many courses to students anywhere. With an Enterprise License, these courses can be taught to every student on all their campuses as well as to all company employees, irrespective of company size, for years to come.

The Maintenance Technician Training Software Bundle also has been proven to be popular among global corporations, smaller companies, and organizations, as they can now be availed with a 31% discount per site, or %50 discount for all sites (Enterprise License). It will allow them access to academically designed curriculums according to the standards and comply with the American Higher Education Commission. With the two perpetual unlimited student licenses, companies can skip the hassle of formulating the framework of a new curriculum from scratch through the availability of these predesigned content modules and courses. The Maintenance Technician Training Software Bundle includes 8-course software titles. Best suited for Industrial maintenance technicians, it includes PLC, PAC, HMI, VFD, motor and controls training, the troubleshooting trainer, DeviceNet, and the fluid power course.

As per the initial reports, there are no hidden charges, terms, or conditions when purchasing ‘The Maintenance Technician Training Software Bundle’ perpetual Enterprise License. With that license, there can be unlimited installations, and there is also no limit on the number of students who can take the courses in this software bundle.

Once downloaded, it can be accessed without the internet, making it a fit for distance learning as it is highly feasible to be accessed anywhere, anytime. The lab manual is also provided for the convenience of course instructors. Additionally, each course in the bundle is a highly interactive Windows software program with built-in simulations, audio narration, and extra learning material.

Perpetual Site licenses (SL) and perpetual Enterprise licenses (EL) are available at Business Industrial Network (bin95.com). These industrial control systems training courses (Koldwater Rockwell automation training series) for industrial electrical technicians and maintenance are an excellent low-cost way to enhance the learning in City College, Community College, and Technical University programs, as well as being an out-of-the-box solution for corporate training and development departments.

Corporate training directors, The Brotherhood of Electrical Workers locals, training centers, and technical college instructors use these automation control certificate courseware programs to train in industrial automation control and enhance industrial electricians’ electrical training, worldwide.

For more details and information, visit Industrial Maintenance Technician Training

New Free Automation Training

If you have not visited https://www.youtube.com/user/bin952 lately, you should as we have added a lot more training videos. Bellow are some examples of industrial automation training videos recently added.

Industrial Automation Technician Training

With this Industrial Automation Technician Training Bundle of technical certificate courses, you save 32%! The Industrial Automation Specialist Training bundle includes the 7 following certificate course software topics. PLC training, PAC, HMI, VFD, motor controls trainer, troubleshooting trainer and the DeviceNet tutor.

Reliability Engineer & Maintenance Planning Jobs

📈 Reliability engineers make great maintenance planners. 📈

Reliability Engineers moving into Maintenance Planner jobs is a common occurrence. In viewing the video introducing the role of a maintenance planner, we can see why. The video expands on the maintenance planner job description.

It is not uncommon for reliability engineers to transition into maintenance planner roles. This shift often occurs due to the overlapping skill sets and expertise required for both positions.

Maintenance Planners:

Maintenance planners coordinate and schedule maintenance activities, ensuring that equipment and machinery are properly maintained to minimize downtime and maximize productivity. They work closely with maintenance teams, production departments, and other stakeholders to develop comprehensive maintenance plans.

Reliability Engineers:

On the other hand, reliability engineers focus on analyzing data, identifying potential issues, and implementing strategies to improve equipment reliability. Their work involves conducting failure analysis, developing preventive maintenance programs, and optimizing asset performance.

Given their responsibilities and knowledge base similarities, reliability engineers often find it a natural progression to move into maintenance planner roles. They already deeply understand equipment performance metrics, failure modes, and maintenance strategies. Additionally, their analytical skills enable them to prioritize tasks and allocate resources efficiently and effectively.

In a maintenance planner job description, employers may seek professionals with experience as reliability engineers or similar technical backgrounds. This preference is primarily driven by the belief that individuals with this background can bring valuable insights into optimizing preventive maintenance schedules and enhancing overall equipment reliability.

The transition from a reliability engineer to a maintenance planner can be seen as a logical career progression that leverages existing skills while expanding into broader operational planning responsibilities within an organization’s maintenance department.

Reduce Corporate Training Videos Cost for In-House Training

The article below compares custom training videos cost to standard training video cost. In this example, Lean Manucaring videos are used. The approach can be applied to any training video topic.

I hope you like it and share it with others.

Source: Comparing Costs of Corporate Training Videos for In-House Training – Industrial Training

Pneumatic – Hydraulic Fluid Power Training

The Fluid Power Trainer 5.3 Upgrade has just rolled out!

We had to upgrade some of the technology behind the certificate course software, so while there updated several of the learning modules. The Site & Enterprise Licensing is already world-renowned to be the most flexible and cost-effective pneumatic/hydraulic training solution; now just got better! As did the single Student License.

Pneumatic – Hydraulic Fluid Power training certificate course.

Great for a hydraulic engineering preparation course or refresher and for maintenance.

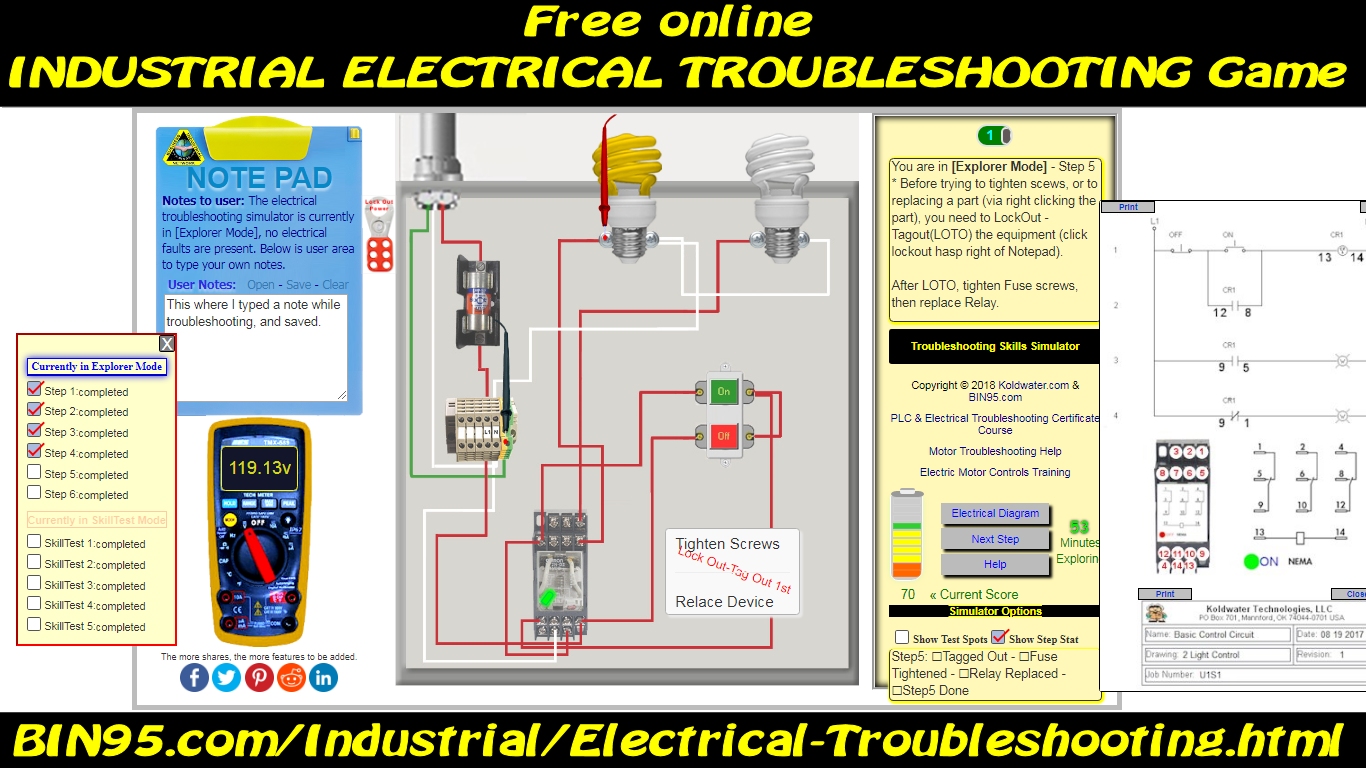

Electrical Troubleshooting Simulator

NEW Free Online Electrical Troubleshooting simulator:

https://bin95.com/industrial/electrical-troubleshooting.html Updated 4/25/2022

This online electrical troubleshooting training simulator game app is like no other. It is compatible with smartphones, tablets, PC, Mac, and even 4kTV! Designed for Chrome and IE browsers (works with other browsers too, but currently not compatible with firefox). Unlike others, this training app includes the official 6-step lockout tag-out safety procedure training, also includes environmental and intermittent simulated electrical faults, and allows you to use all 5 senses to troubleshoot!

O.E.T.S: [pronounced ‘oats’] – The only free Online Electrical Troubleshooting Simulator in the world.

Have you had your OETS today?

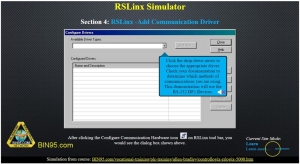

Introduction to RSLinx classic for PLC communication?

I highly recommend you check out the RSLinx article link below. The added RSLinx simulator/game makes it not just reading, but an experience. Hopefully a fun one!

There is also an RSLinx/RSLogix 5000 FAQ sheet in the article too. With the introductory video, a little something for everyone. If you are interested in industrial automation anyway.

Introduction to RSLinks Classic article.

Reliability Analysis Example of Drinking Glasses

The video below will give you a reliability analysis example applied to drinking glasses. It was created from a section of the Reliability Engineering Training Course PowerPoint Download. This small sample starts out by answering What is the Reliability? Then immediately dives into the sample topic at hand …

What is the Reliability of this Glass?

Applying reliability analysis statistics.

Summary: In the above video you learned the following …

Reliability Analysis Example Key Points:

- A reliability analysis does not predict the future, it only predicts the chance of a possible future.

- How the drinking glass is used has the most effect on reliability.

- Obtaining reliability analysis statistics like the number and time of failures is one of the first steps in reliability analysis.

- We need to convert the rate of failure to the chance of failure.

- Random failures are preventable.

To learn more, download the full PowerPoint Reliability Engineering Training

Root Cause Failure Analysis, RCFA Meaning – YouTube

Root Cause Failure Analysis – RCFA Meaning

A small sample from the Rotating Equipment Reliability Excellence Training Course PowerPoint Bundle download. Covered in this video are RCFA Fundamentals and The RCFA Process, touching on fishbone failure analysis and other RCFA methods to find the root cause of failure.

An excerpt from the 4-day course “Rotating Equipment Reliability” course PowerPoint download.

Maintenance Planning and Scheduling Job Description

Excerpt from the Preventive Maintenance Planner Scheduler Course PowerPoint. Maintenance Planner Scheduler job description is where we start.

Source: Maintenance Planner Scheduler Job Description

Here are some more samples from that course …

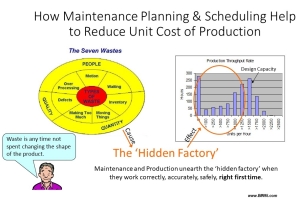

How Maintenance Planning & Scheduling Help to Reduce Unit Cost of Production

This slide shows a graph of how the ‘hidden factory’ can be spotted. It indicates the seven causes of waste that produce the ‘hidden factory’. All the lost production and the below-full-capacity production represent the ‘hidden factory’. The message for Maintenance Planners is that the work they do preparing for maintenance aids in recovering and preventing lost production by giving the maintainers the best opportunity to do high-quality work that improves plant reliability and extends the run-time between failures.

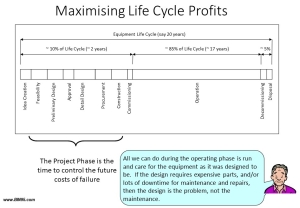

Maximizing Life Cycle Profits

It is important to realize that operating costs can only be changed and removed during the design and project phase of the life-cycle. Once plant and equipment are in place, all its associated requirements must be met. Those necessary costs cannot be lowered without increasing the risk of failure by reducing the item’s reliability, with subsequent poor effects on production output.

The Maintenance Planner can do nothing to change what happened during the project phase, it is all history by the time they work in the business. But they can change the project decisions to be made in the future if they capture good, sound records of the performance and costs of the production equipment used in their operation. With believable evidence of equipment performance provided by the Maintenance Planner, future project designers will make better decisions in designing and selecting a future operating plant.

To download all 229 slides with instructor notes, see Maintenance Planning and Scheduling course PowerPoint download. I hope you found this interesting and share it with others.

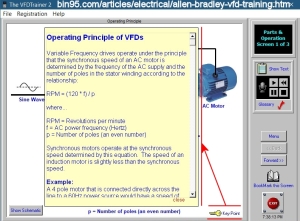

Sizing VFD for Motors

Allen Bradley VFD Training key points samples. Samples: Freak drive operating principles, sizing VFD for motor, variable frequency operating temperatures.

Source: Allen Bradley VFD Training, and Sizing VFD for Motor.

How do you size a VFD drive for an application and feel confident it’s going to work?

You must understand the requirements of the load. You should also understand the difference between horsepower and torque. Both torque and horsepower must be carefully examined.

Key VFD specifications:

While there are many specifications associated with the variable frequency drive, the following are the most important. Continued in the full article at https://bin95.com/articles/electrical/allen-bradley-vfd-training.htm

VFD Applications to watch out for…

If you answer any of the following questions with YES, be extra careful in your VFD selection and setup parameters of the VFD.

Will the VFD drive operate more than one motor?

The total peak currents of all motor loads under the worst operating conditions must be calculated. The VFD must be sized based on this maximum current requirement. Additionally, individual motor protection must be provided here for each motor.

Is the VFD motor load considered hard to start?

These are the motors that dim the lights in the building when you hit the start button. Remember, the VFD is limited in the amount of overcurrent it can produce for a given period of time. These applications may require oversizing of the VFD for higher current demands.

Are there power factor correction capacitors being switched or existing on the intended motor loads?

Switching of power factor capacitors usually generates power disturbances in the distribution system. Many VFDs can and will be affected by this. Isolation transformers or line reactors may be required for these applications. Power factor correction at VFD-powered motor loads is …

Continued in the full article at https://bin95.com/articles/electrical/allen-bradley-vfd-training.htm

I hope you like and share with others. Have a great holiday coming up.